Colorful life

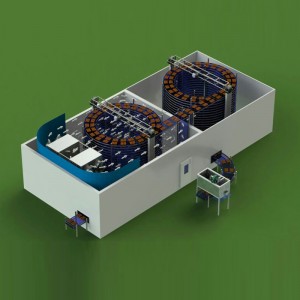

Rotary oven

Rotary oven

Introduction:

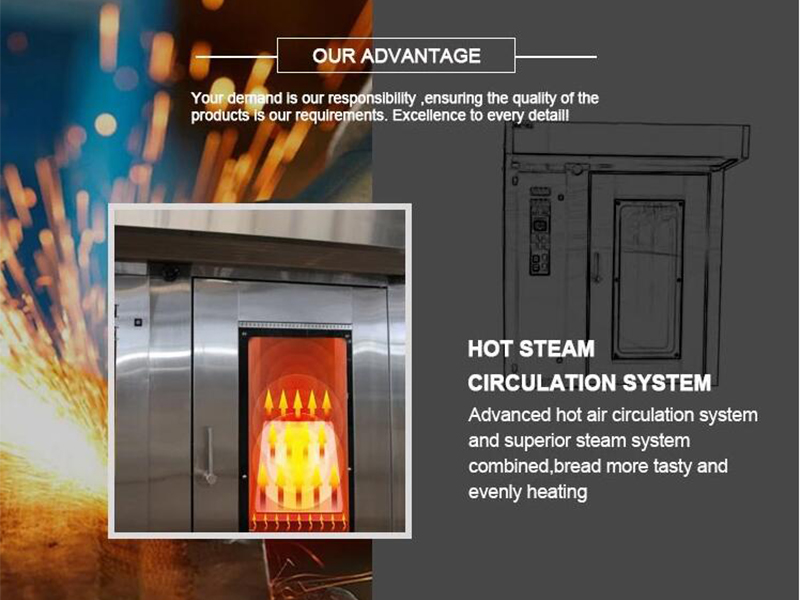

Our rotary oven boast assure large baking area with minimum surface requirement. And also with a steam system which provides high volume, shine, texture and crust in the market. It is industrial & commercial baking oven.

The energy required in the baking process is fine tuned by an energy saving heating element, a well balanced blower with precision nozzle which distributes the exact amount of heat necessary into the baking chamber.

Features:

1. Even Baking.

2. Minimum baking time.

3. Programmable timers with digital display to control baking time.

4. Low Energy & Fuel Consumption.

5. Automatic heat & time setting.

6. Apply to bake all kinds of bread, cake, cookie, biscuit and pasties.

7. The burner imported from Japan with low oil consumption and low exhaust emission.

8. The inside and outside of the oven is stainless steel.

9. The diesel consumption is about 3.2L/hour for diesel type. The electric consumption is 36 for electric type. The gas type needs 3.5L per hour.

10. Baking temperature is set and heating begins. When temperature reaches the set value, heat preservation will continue for 10 to 15 minutes to make temperature between the inside and outside of the stove balanced.

11. It is used for industrial & commercial cake oven and other breads oven.

Rotary oven:

1. RIELLO burner to resist 1200℃.

2. 7 inch LCD screen for the baker to check the rest time easily.

3. Steam system can change 8 kilogram water into steam within 20 seconds.

4. Position device on top to keep the trolley facing to the door after stopping.

5. 360°circling hot air to keep equal and optimal fire.

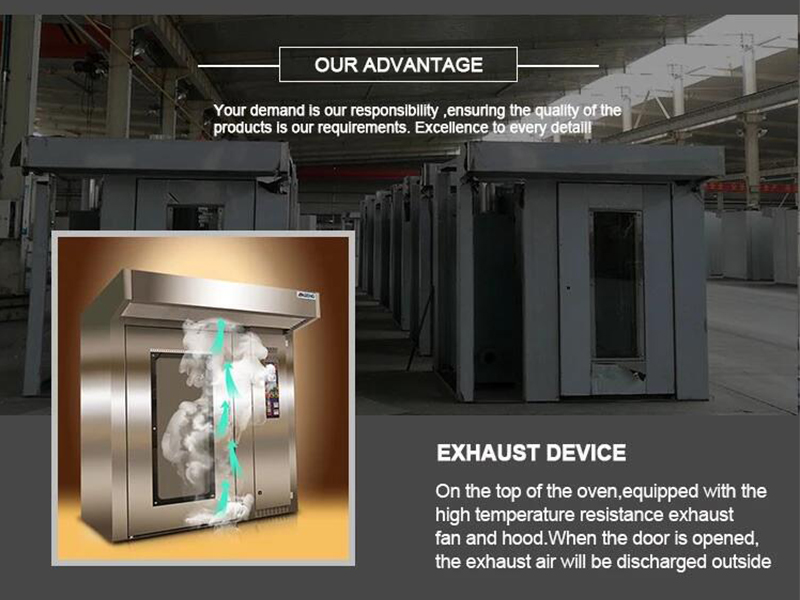

6. Air exhauster and fume collecting hood on top which is environmental protected.

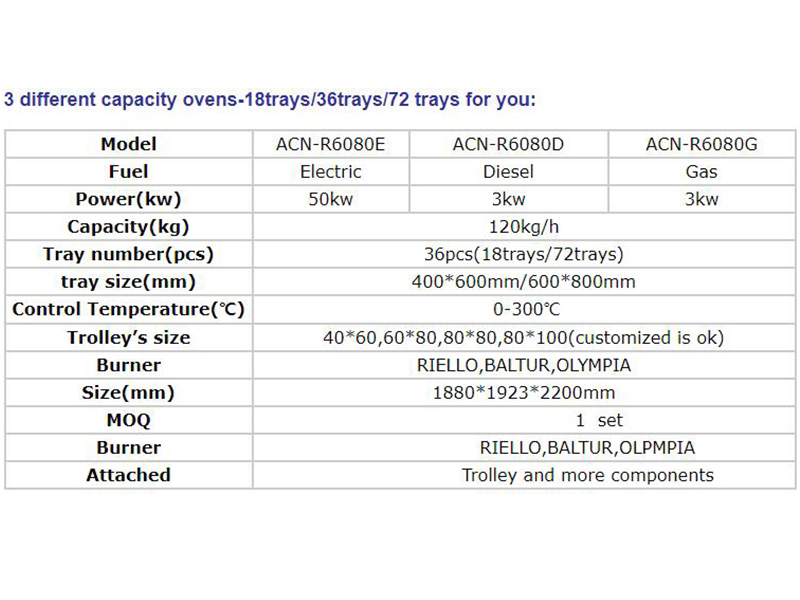

Specification:

| Model | Applicable baking tray size(mm) | Baking area(㎡) | Maximum yield (According to bread/kg) | Power(kw) | Dimensions(mm) | Weight(kg) |

| R4060D | 400*600 16-18 trays | 4.3 | 50 | Diesel 1.6 | 1650x1280x2300 | 650 |

| R4060E | Electric 37.5 | 1650x1280x2300 | ||||

| R4060G | Gas1.6 | 1650x1280x2300 | ||||

| R6080D | 600*800 16-18 trays 400*600 32-36 trays |

5.7-8.6 | 120 | Diesel 1.6 | 2000x1550x2300 | 1100 |

| R6080E | Electric 46.5 | 2000x1550x2300 | ||||

| R6080G | Gas 1.6 | 2000x1550x2300 | ||||

| R80100D | 800*1000 16-18trays 450-750-2trollry 32-36 trays460*760-2trollry 32-36trays |

9.7-14.5 | 195 | Diesel 2.5 | 2300X1850x2370 | 1400 |

| R80100E | Electric 78 | 2300X1850x2370 | ||||

| R80100G | Gas 2.5 | 2300X1850x2370 | ||||

| R80120D | 800*1200 16-18trays 600*750-2trollry 32-36trays400*600-2trollry 64-72trays |

12.8-17.2 | 240 | Diesel 4.7 | 2450x1970x2500 | 1800 |

| R80120E | Electric 117 | 2450x1970x2500 | ||||

| R80120G | Gas 4.7 | 2450x1970x2500 |

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.