Colorful life

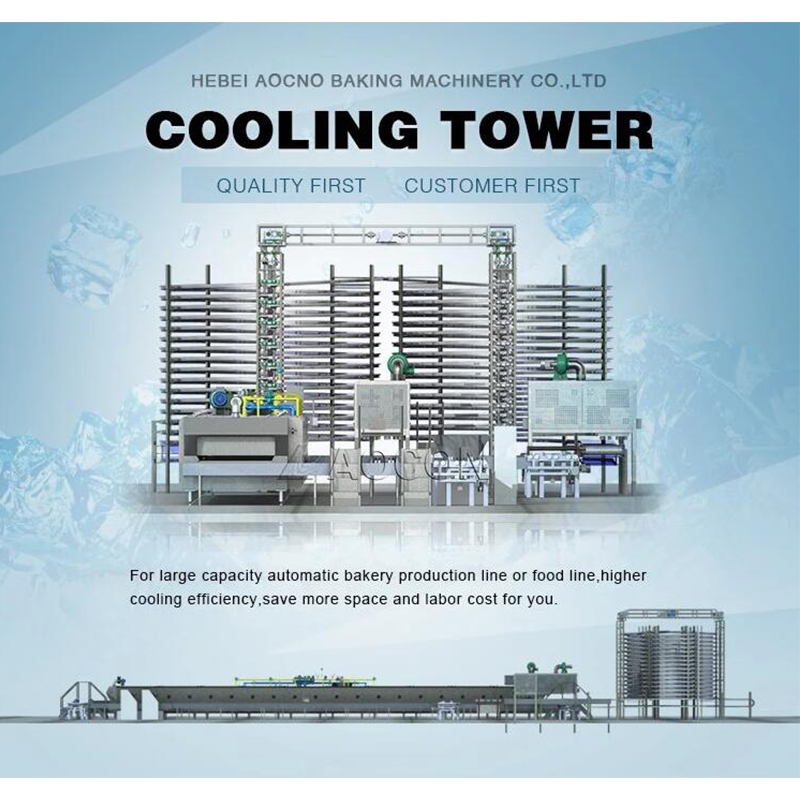

Bread cooler

Bread cooler

Temperature: room temperature

Why cool bread?

1. The bread crust just came out of the oven is hard outside and soft inside. At this time, the packaging will easily damage the bread crust and damage the bread tissue.

2. The temperature of the freshly baked bread is high. When it is cold after packaging, the water vapor will condense, which may lead to quality deterioration, including microbial contamination and water infiltration of the bread tissue.

During the cooling process of the bread, the temperature gradually decreases, the outer skin cools down quickly, and the inner skin cools down slowly, forming a temperature gradient difference. As the internal heat spreads outward, the water is also continuously lost, and about 1% ~ 3.5% is lost at this time, and it is cooled until Can be packed at room temperature.

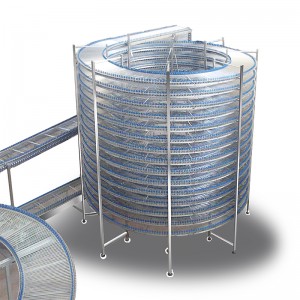

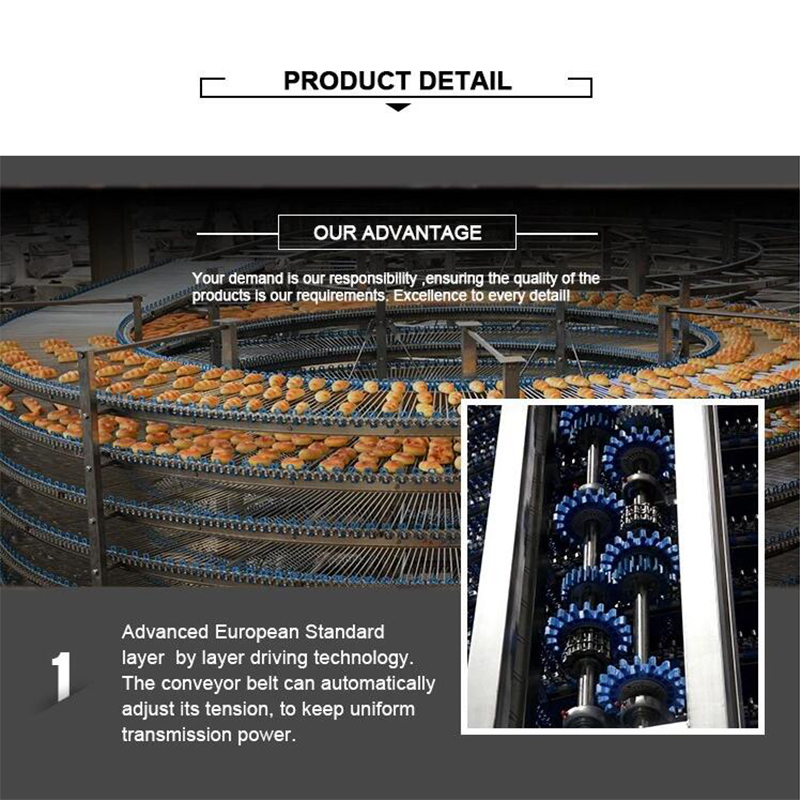

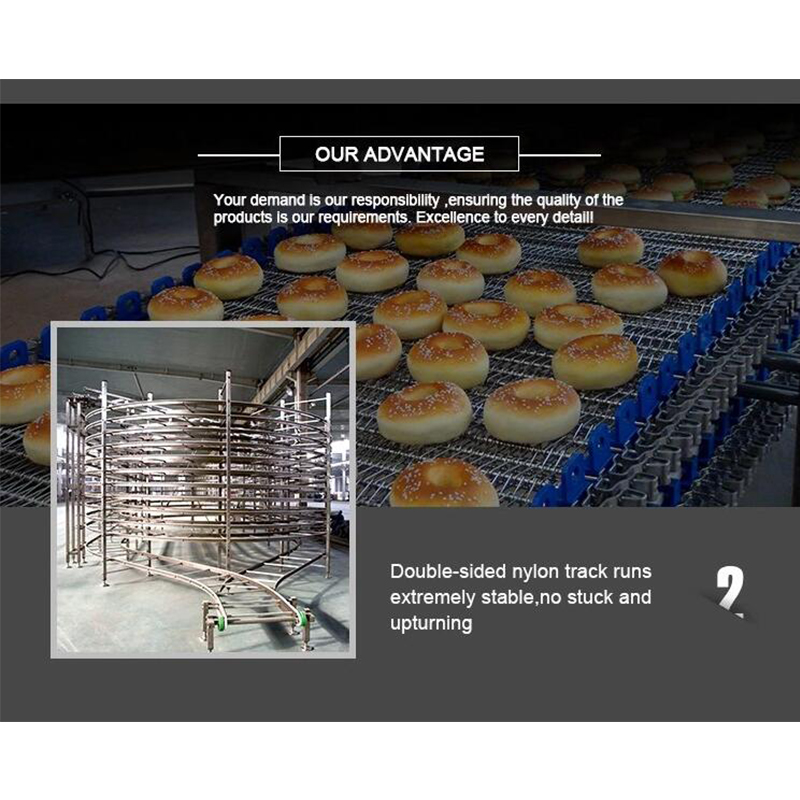

The spiral bread cooler is designed for large-scale bread production lines. This machine is equipped with layer by layer transmission technology, The gear motor drives the gear on every layer through a spindles , and the gear stir the convey belt for movement. Every gear has intelligent power transmitter which can adjust the convey power.

After the bread is baked, it reaches the bread cooler through a conveyor belt, and then the natural cooling in the spiral cooling tower & conveyor is completed to reduce the bread temperature to the same as room temperature. Then package.

Features:

- Double side nylon card track is stable when it is in operation, it will never get stucked or upturning.

2. Every belt can adjust the power automatically and keep the power equal because it has intelligent transmission technology. And its speed is Variable.

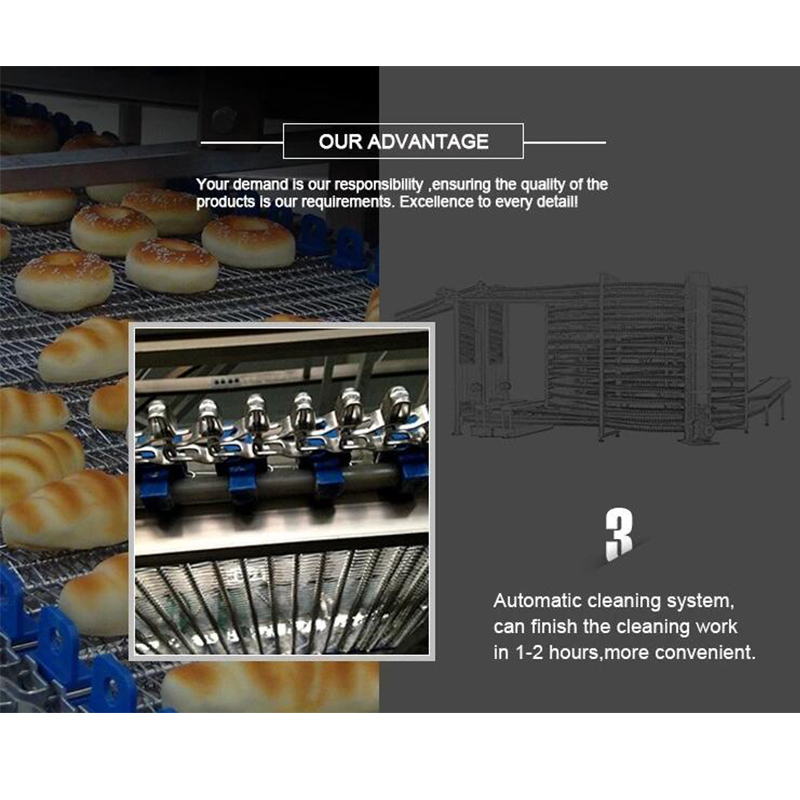

3. We choose high strength nylon card track and low friction food grade pp guide rail for it.And it has automatic lubrication system so you do not need to add lubricating oil and no need to repair or change any components within many years.

4. We can design different Input and output directions according to customer;s workshop’s area, such as low input and high output, high input and low output, two input and two output, three input and three output, the last kind is elliptic type.

5. It saves spaces and guaranteeing high efficiency.

6. Adapted to bakery products, vegetables, fruit, meat and fish etc.

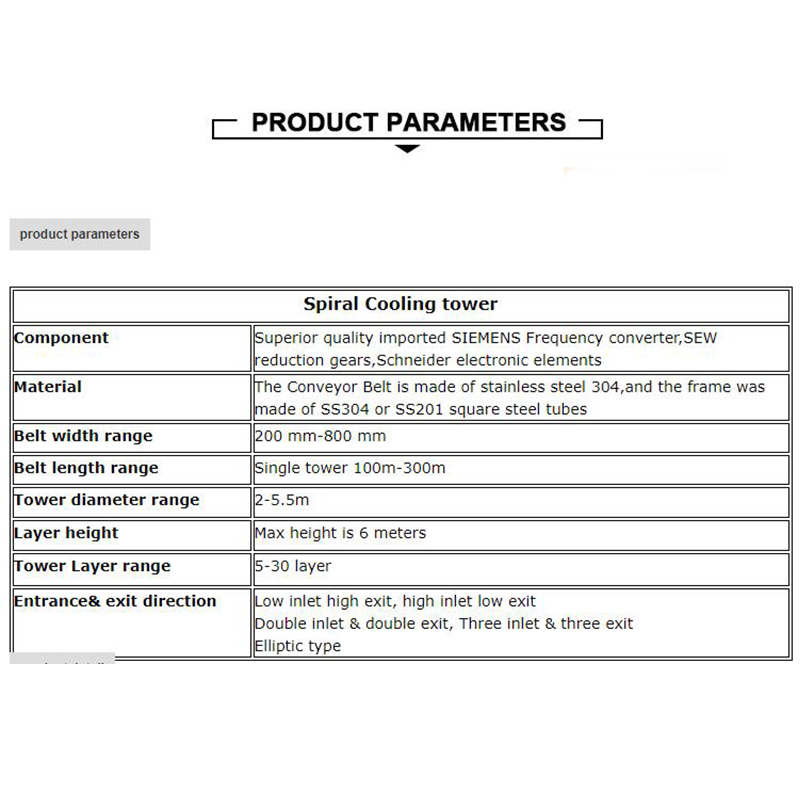

7. The conveyor belt is stainless steel 304. To grantee it is durable, the frame is ss304 or ss201 square steel tube.

8. The spiral cooler quip with automatic cleaning device and will do the cleaning automatically.There are some food scraps and stain during the operation of the tower, our engineers invent automatic cleaning device which can finish cleaning work within 1-2 hours and also dry it automatically.We have three kinds: single tower, double towers, elliptic tower.

9. It has variable-frequence, gear motor and Germany Schnelder Electric components.

10. Belt conveyor can be bends, slopes or spirals.

It is customized for the following elements:

1. Material, length and width of the conveyor belt.

2. The height, diameter and layers quantity of the tower.

3. In feed and out feed direction.

4. Shape of the tower (round, elliptic).

5. Material of the frame.

6. The brand of the reduction motor, bearing, and the Inverter frequency device and screen.

In feed and out feed direction and Shape of the tower (round, oval, vertical) is customized.

Please note us the capacity, cooling time and the size of the food you make.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.